Where the metal meets with technicality

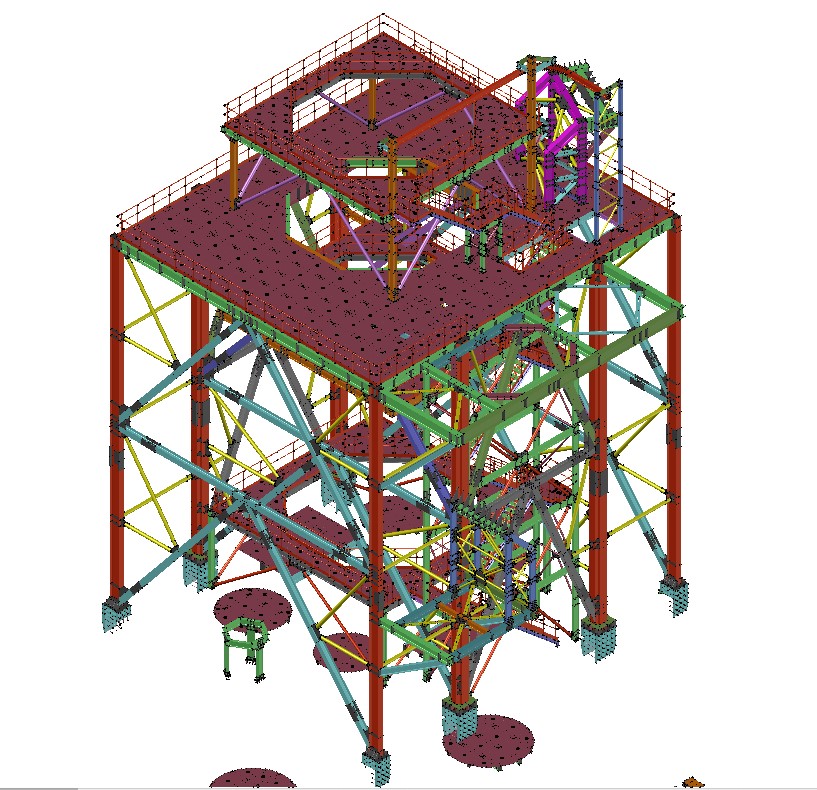

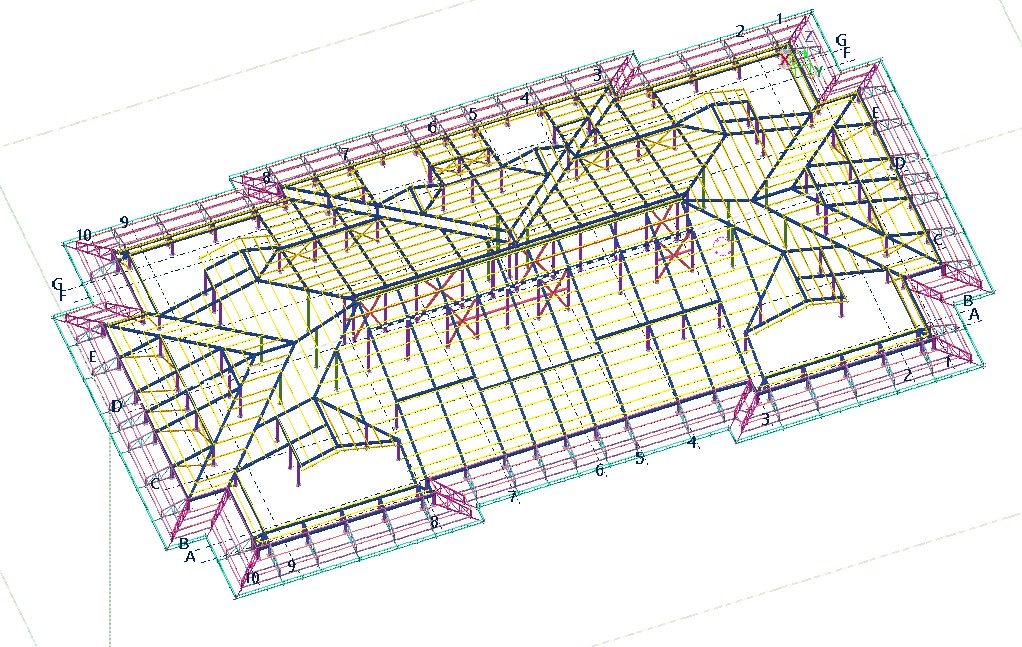

Hot Rolled Steel Construction Systems; are designed considering every function of the building begining from the project phase. The safety and the quality standart of the building are also ignored at the design process of the structure. Accurate and detailed project planning purposes; to provide the most safe and economic structure to the user on time.

It must have been correct to think the job half done when the project was accurate designed…

Cold formed steel structures are built with galvanised or raw steel coils using cold forming techniques. The most commonly used and the most appropriate technique is using roll-forming. By this way the profiles are manufactured at the required length and drilled even for very small amounts.

Light gauge profile has a high load carrying capacity in comparison…

Houses using steel frames can be constructed very safe. Steel structures can absorb earthquke energy due to their flexiblity. Shorter construction time is another important advantage because of their prefabricated manufacture.

There are two main types of structural load carrying systems for residential buildings…

Metal roofing systems are applicated with a high level of insulation performance, long lasting, functional and aesthetic solutions. These systems are standing seam, trapezoidal and sandwich panels. The type of the systems is determined by the architecture, function and the need of insulation.

Metal standing seam systems can be composed of different metals…

Where the metal meets with technicality

Recent Works

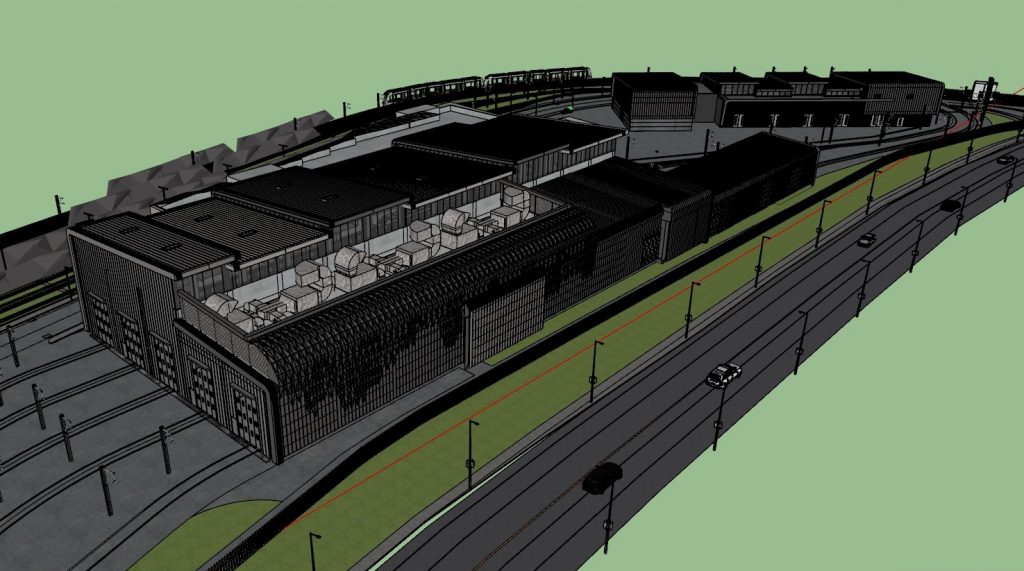

Eminönü Alibeyköy Tram Line

Doğuş İnşaat

Aslan Cement - Ceta Makina

Cer İstanbul - Ege Yapı

Galataport İstanbul Project

Perspektif Yapı