Company

METEK is established to build safe and durable structures by adhering to the principles of engineering. The company operates in the steel construction and metal roofing and cladding areas that has intensive metal usage. We achieved to take a part of many and different projects at design, manufacture and insallation.

Our company name is the combination of the two words “metal” and “technical” and we are trying to put them correctly together at the right form, right place and right time.

Our main areas of activity; steel construction of industrial and residential buildings, metal roofing and cladding. Steel construction is built from design to the finishing taking into account every function. In particular, our company is ready to offer optimum solutions from static and dynamic design of structures up to the cladding of the buildings.

Aesthetic, economical and reliable solutions are developed according to the architecture. Light-gauge profiles that produced by using cold forming technology are highly used to obtain light solutions. Metal roofing and cladding systems such as trapeze sheet, sandwich panel and particularly the metal standing seam system applications are made.

Factory

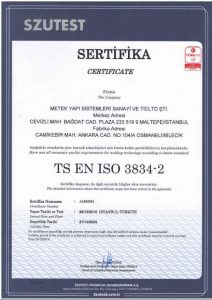

Our factory; Osmaneli / Bilecik 50,000m2 installed in an open space in 7.200m2 closed area; ISO9001, EN 1090-1 and is working to complete our services having quality control system certification to EN 3834-2. Thin-walled profile roll-form line is engaged in manufacturing and h = t = 4mm up to 300mm capacity computer-controlled automatic drilling and can cut. Total capacity of our production line including roll-form 1.600to / month ‘is.

the most accurate and fastest solution through our strong machinery park we yaratabilmekt our own constitution. The richness of our staff makes it possible to work 7/24. To be in the center can be reached our region allows us quick access to many places in Turkey.

Our factory has been built into a large area day by day continues to expand. Each newly created indoor and outdoor areas are equipped with special machines we buy following the current technology. principle to mechanization and the use of technology, our company is taking the necessary steps in this direction.

Factory dominated the technical and administrative office provides effective monitoring and rapid reaction advantages. However, all indoor and outdoor areas that can monitor the camera system from the factory office, head office or from the mobile recognizes the possibility of rapid intervention in the current functioning of the desired area.

Targets

METEK, has its own principle firstly to correct use METEK, has its own principle firstly to correct use of technique or in other words practical application of the theory of engineering. One of our goals is to give customers complete engineering services. We beleive that the engineering is a natural science. For correct application of engineering, the nature (earthquake, gravity, expansion, etc.) has to be good observed and solutions that harmonious with nature should be developed.

Structures have to resist to many forces but should not be cumbersome and complicated. There are so many samples in nature. For instance, how light is a spider’s web but so powerful and flexible. Using the materials and details that developed based on natural science will be our best goal. The main principles are correct identification of the natural effects, correct choice of materials, correct details and surely the right application.

Our company’s most imported goals are to develop itself continuously and being customer-project oriented. Other important goals; provide solutions to customers at every respect, promise what we can, be trustful and make all possible effort to finish the job correctly and at time.

Quality Management System

Our factory is ISO9001, EN 1090-1 and is working to complete our services having quality control system certification to EN 3834-2. The quality management system starts with a nominal purchase the material process of product certificates, test reports, technical data, material safety certificates controls the approval of the materials after in accordance with relevant standards as set in the factory. Packing, storage and exposure control criteria throughout the process.

Manufacturing drawings held after checks materials processing factory, respectively SA2,5 quality blasting and shop primer application after cutting, punching, bending, roof and subjected to processes such as welding. Whereby the profile and the plate can be transferred to the paint shop in accordance with the project from exposure to the corrosive effect. Hot-dip galvanized for covering the oil, rust and manufacture as being free of tempering finished materials necessary mounting holes, vents and to be made for access to the point of the reach of zinc is prepared including the design. The whole process will advance approval by quality control engineers in accordance with the relevant standards.

Submerged arc welding, gas metal arc welding and commonly used methods such as electric arc welding machines and latest technology in applied by experienced staff. All manufacturing procedures in the construction method in accordance with the criteria set out in the designated surveillance and test reports are described at the beginning of the project. Welding method, welding instructions and repairs the criteria defined at the start of the project. source at a frequency determined by non-destructive testing are tested. If necessary, 3rd party inspection company to check the documentation for service by their impartial reporting to additionally provided.

Factory using approved packing list with the method specified in the materials sent to the construction site assembly phase to properly versed in the appropriate fasteners are fastened to the criteria by staff. After the installation is delivered after the necessary touches to the approval of the quality control team.

Safety System, Enviromental Management

Companies in the sector experienced C-class in our on-site and B-class safety experts in addition to public health and the class of service received from the security department occupational safety specialist, occupational physicians and allied health personnel team safety is the functioning of our system. All data acquired factory manager, production supervisor, project manager, site supervisor, such as projects related to key management personnel are also reminded forwarding company. In addition to the technical team, mainly blue-collar personnel also often are given training.

Occupational health and safety as a priority criterion that determines our company project to start in order to supervise the staff in any environment where there is no proper conditions are approval. our compliance with OHS team is essential for every site.

ISO 14001 Environmental Management System and OHSAS 18001 for Occupational Health and Safety Management System certification has been initiated and the procedure is planned in 2016.